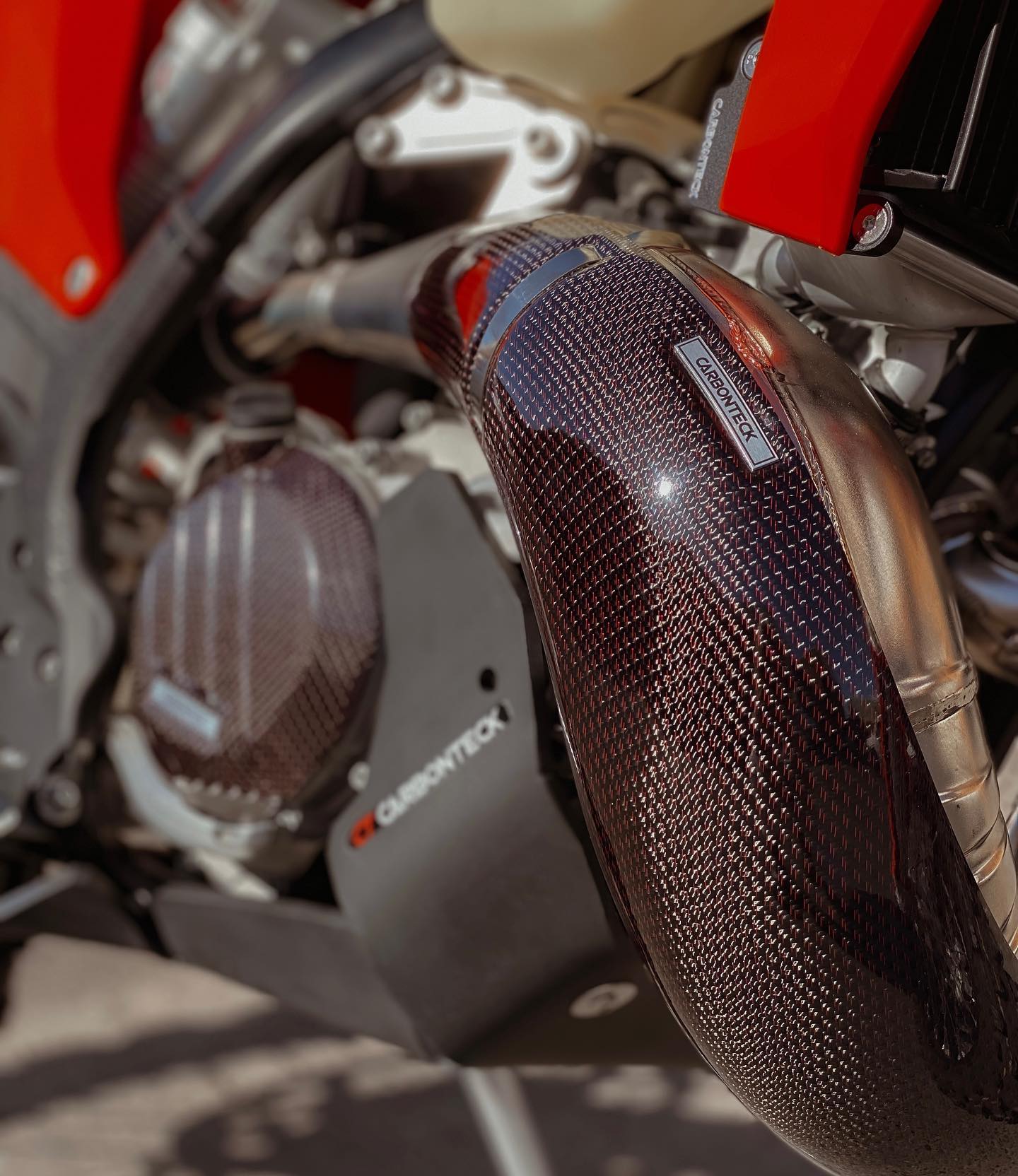

Carbonteck

Carbon Exhaust Guard

Carbon Exhaust Guard

Couldn't load pickup availability

The Carbonteck kevlar exhaust guards are manufactured with a process called vacuum bag infusing. Inside the part you will find 2 layers of 170g twirl carbon, 1 layer of Kevlar, 4 layers of 600g biaxl glass and 1 layer of 400g twirl glass.

All these materials get vacuumed in a mould at 1 ton per square foot and then infused with high heat epoxy from a company in France. After infusing the part gets post cured with the mould in a oven for 5 hours. After demoulding, the part goes back in the oven for another 12 hours until TG is reached.

The part then gets trimmed and special high heat silicone strips get attached on the inside. The purpose of the strips is to create a cushion between the pipe and the guard and to create a gap between the pipe and the guard for air so that the pipe runs cooler. This is a very expensive manufacturing process but the end result is a super strong guard and super light guard for your fragile pipe. The final product weighs only 700 grams.